In between doing various other things, today, I spent some time getting photos "more organizee" so I could explain how I built myself a secondary work surface, in a corner of a bedroom. There wasn't much space, and what was there needed a custom-shaped workbench surface ... which explains this next image:

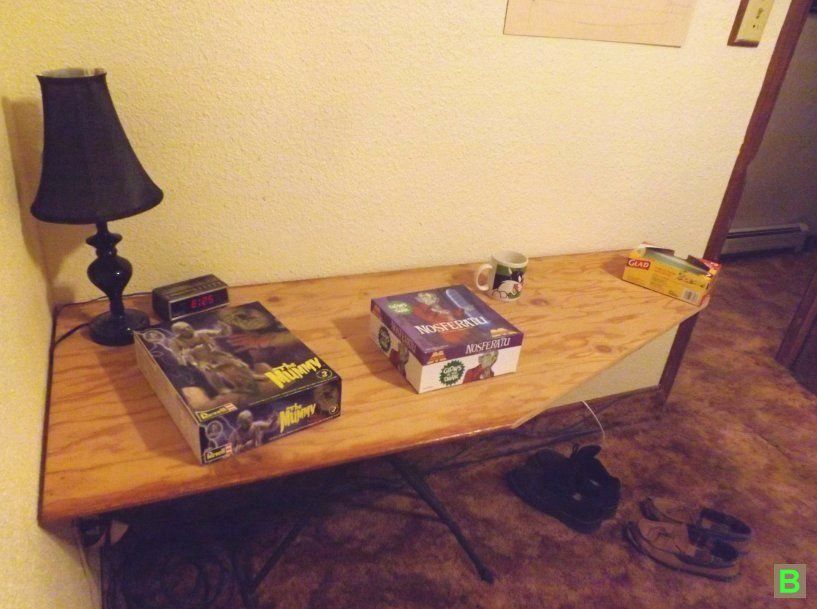

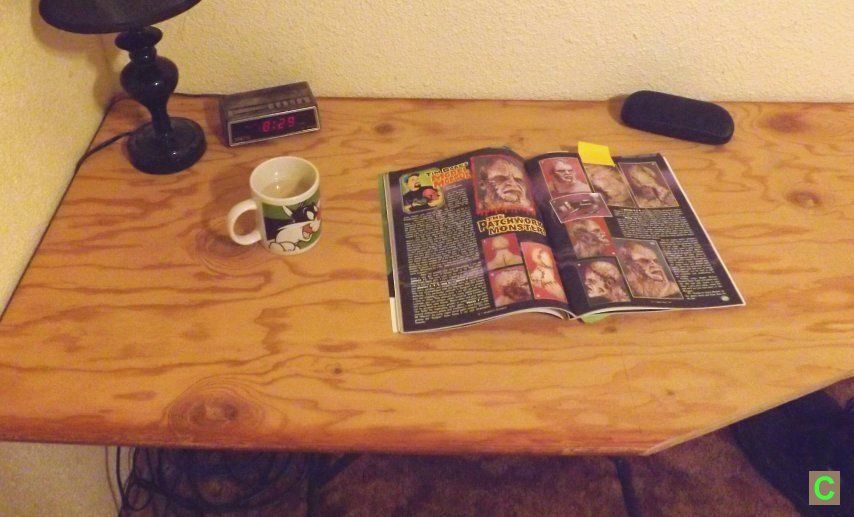

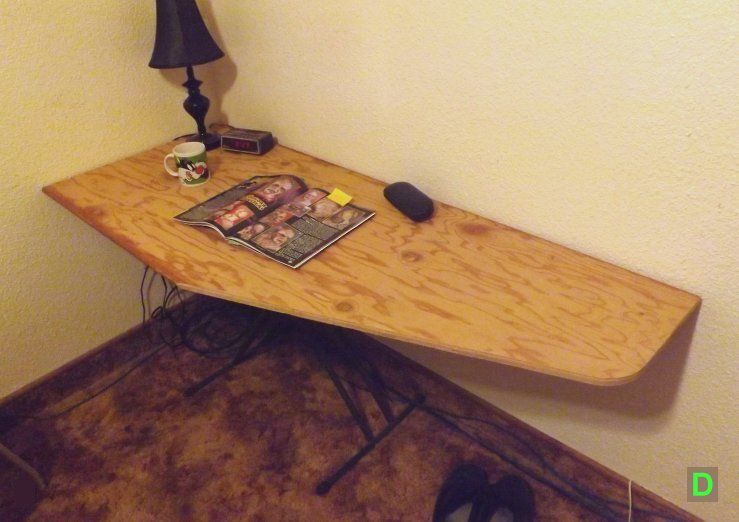

Photo A is a bit out of strict order, actual-sequence-wise (it's from about a week ago; not "at the start") ... but most people may not notice that from the details; and it's probably the best photo I have, as far as showing how the actual shape is basically a standard rectangle, which has had one long "corner" removed.

The main reason for wanting a non-rectangle is that I've slept in this bedroom for a dozen years now, and tried one desk or bench or portable table after another in the one-and-only place where such things could possibly fit into that room ... and anything square isn't a big enough work surface; and anything rectangular wants to bang the heck out of one's knees, entering or exiting the room. (Or worse, far more delicate parts: since desk corners tend to be at crotch height!?!)

Besides the slight oddness of the "as viewed from above" shape of the work surface, there's another major complication I threw in: I didn't want "legs" on this workbench, if I could help it. So, I basically had to either invent some gravity-defying machinery to hold the surface up ... or bolt supports to the corner walls.

Photos B, C, D, and E show how I've had that set up, mainly just for testing purposes, for most of a year now. I mainly wanted to know if I'd kill myself, or not, when entering or exiting the room. It passed that test, after a few minor adjustments ... so now it's time to make that a more permanent, useful work surface.

For anyone wondering: that chunk of used plywood used to be a closet door or something, from upstairs, that I'd cut roughly to shape, long ago (and then later did a bit of refining on) ... and then just plopped the board on top of a portable table. Gravity was the only support. That didn't make it very usable, except as a big shelf for holding clutter ... but even doing that was a step in the right direction, as having it in the room let me know if shape-and-size would work well.

A big part of the reason for showing that first image, which showed the custom-shaped board when it was just leaning up against a wall, was because camera distortion in most other images, makes it really hard to figure out the true shape. Looks more complicated than it is, or a different size or proportions, in some of these other shots ... hence showing that "overhead view" angle, first. Anyway ... moving on, to more recent work: in making that "tested" shape permanent.

Photo F shows the support board that will hold the shelf's back edge up. It's just a long skinny chunk of pine: basically, one inch thick by about four inches wide, by whatever the measurement was (been a long time since I first cut those boards!), from the left side to the right side of the work surface. (Give or take.)

Photo G shows the same basic idea; except that I used a shorter board, to hold up the left side of the work surface.

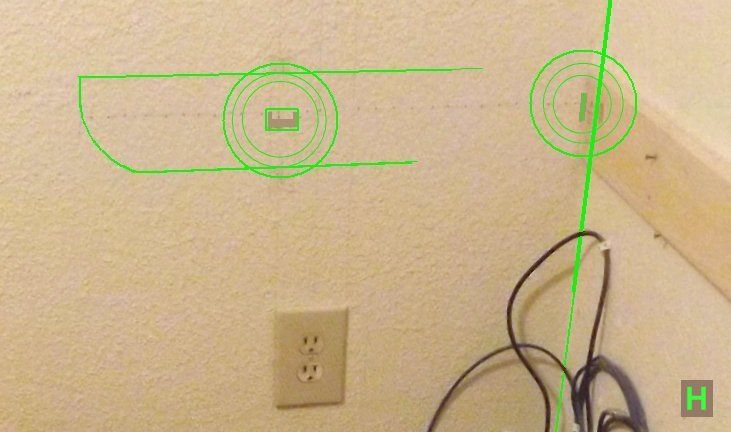

Photo H gives a better idea of what the process was, for locating the wall's interior "studs" -- that is, the actual upright chunks of wood holding up the visible part of the wall, and giving the wall good support, from inside.

Some tips, if you've never done this kind of thing:

I've found that with old houses that have seen a lot of prior renovation or upgrade work, you can't expect the uprights to be at any predictable and/or consistent spacing, from side to side ... so, I took a small diameter drill bit, and just drilled holes (in a spot where they'd be covered up, at a later point) in a fairly straight line, from side to side. The holes are spaced roughly 3/4 of an inch apart. When there was some solid wood behind the sheetrock or drywall paneling, I marked that location with a medium Sharpie marker, and kept going down the line. When I'd found the approximate location of the uprights or studs, I went back to those same basic locations, and drilled additional holes. Doing so told me how wide each upright actually was -- since I've found over time that sometimes there are two uprights standing, side-by-side, and they are both standard thickness (which is rare, but is nice and sturdy when it happens) ... but I've also found that sometimes what's behind the wall isn't standard thickness (such as in this case!) ... so it's best to know exactly where they begin and end. (As far as left-side to right-side of the uprights.) In this case, what I learned, from drilling lots of holes side-by-side when "looking for" the wooden studs or upright beams behind the walls, was that these uprights were only about 1.25" inches thick; give or take. Maybe 1.50" inches, if I was lucky. But sturdy! Once I saw how thin they were, from side to side, I did a test in a hole or two: threading in those big bolts, ever so slowly, after drilling appropriately-sized starter or pilot holes. Nothing ever fought me, or cracked, or anything like that. Those tests satisfied me that whatever was behind that wall surface was good quality, reliable, very solid wood.

I should mention that really old houses sometimes do not always have "nail plates" over electrical wiring, wherever it passes through wooden wall supports, so if you're dealing with a really old house, definitely take a LOT of care to be sure you're not going to drill holes through electrical wiring, inside the old walls! (But in this case, I knew that wasn't a problem -- and I never hit anything that felt like a nail head, when I was drilling; or worse yet, protective plates over wiring!)

The exploratory holes seen above are already half-dried. I had filled them all back in, using Dap-brand "DryDex" (I'll double-check the name, later; but I think that's the name of it) with no problems. It goes on pink in color, and turns a white color when it's fully dry. I just used an old butter knife to apply that putty.

You can also see a Sur-Form "file" or shaving tool, in some of these photos. I used that to trim down excessive wall texture blobs, as needed, in the areas of the wall where I'd be trying to attach flat boards and/or similar stuff, later on. (These walls had really thick, blobby texturing sprayed onto them.)

With the side wall, what I found was that I was only going to get one firm attachment point ... and I'd just have to make that work. (There was one other, about 3/4 of an inch out from the "back edge" wall ... but it would have been a major pain to try to get anything solid to "grab" into such a tiny spot, in such a difficult location, so after considering that one, I decided against trying to use it.)

The home's owner tells me that there used to be French Doors at roughly that location ... which probably explains a lot of the spacing and thicknesses I found. I don't think I found so much a single "two by four" as two layers of "one-by" lumber ... but again, you gotta use what you have; so when I got around to putting in some fasteners in that single location along the side, I took advantage of the thick-enough wood, and that it extended plenty far, vertically ... and I used strong bolts, rather than drywall screws or nails. I had to drill pilot (starter) holes, at each location, first, and then carefully and slowly turn the bolts in, with a ratchet ... but what I ended up with was two quarter-inch-thick, heavy-threaded bolts holding the sides up. (And many more than that, holding the back edge up!)

The way I got around the lack of a "back corner" support, behind the wall surfaces, was to use two heavy duty "L-brackets," to hold the very-secure back board and the much-less-secure side board tightly together. The two heavy-duty bolts will hold quite a lot of the weight applied to the work surface's left side ... and the "L-brackets" near the back edge of the side board will help to make things that much more solid, rigid, and strong overall. I'd rather over-build something like this, than to have it come crashing down on me, later on!

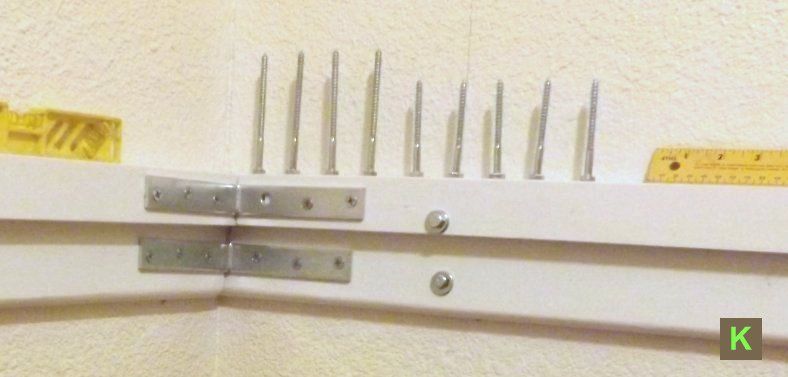

Photos I, J, and K show how I attached the supporting boards.

The wires visible here are just slapped up, out of the way, for now. When I had run new Internet cable throughout the house, I'd left the wires overly long on purpose, any time I wasn't entirely sure where the "end" of the wire would need to be; and thus, wasn't certain of exact length-of-wire needed. Ditto for cable TV style wiring: it's long on purpose, and will be shortened to appropriate length, in due time. But for now ... I just got it up off of the floor: messy or otherwise!

They may be hard to see in these photos, but there are some pencil marks (vertical lines) on various wall surfaces, in some of these shots. Look for them on the "front" wall, especially: the lighting makes them stand out better there. I probably also drew them a bit darker, since I didn't want to have to find the basic area where each upright was, a second time; if/when I later built additional shelves or whatever, above the main work surface.

Along the wall where the back edge of my work surface would be attached, I lucked out. Plenty of good solid locations for attaching stuff, on that wall! They were a bit thin, from side-to-side ... but the "drill lots of holes, to find out what's behind them" trick showed me where everything was; and how thick it all was, too.

Other things I didn't mention, but probably should, would include that I glued and nailed on additional strips of wood, to thicken up the "shelf" as it were, that the horizontal supports would be acting like; when I plopped the main work surface board on top of them. That gave me more "meat" to drill into, later, when I used a bunch of drywall screws to screw the work surface onto the horizontal supports. (By using screws and bolts, everywhere, if I ever need to take it apart, I can.)

Oh, and I primed (by brush, with "Kilz" brand General Purpose primer) both sides of the horizontal supports, once they'd each had the upper strips added to them.

Photos L and M show the top, screwed onto the supporting boards. The screws holding it on aren't visible, here, but that top surface isn't going anywhere!

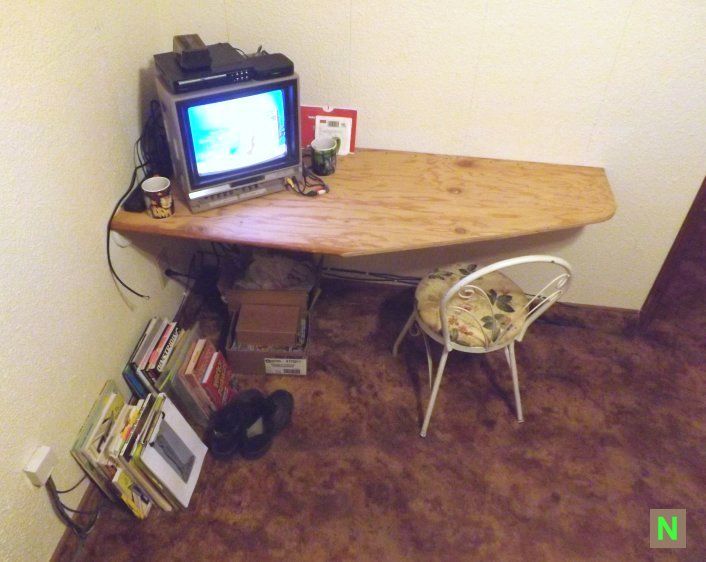

Photos N and O round things out. As you can see by the assorted clutter in the last shot, it's not yet fulfilling it's purposes as a dedicated work surface, just for working on models and what not ... but you can see it's gonna be a pretty strong surface, in most respects, once it's done. It's moving along, step by step ...

The main reason I went into all this detail, word-wise and also picture-wise, is that I figure there may be other guys (or girls?) out there haven't done many major "tearing up a house" sort of projects ... and for them, if they want to actually do something like this, more details and things to look out for, would be helpful.

Keep in mind that what I'm showing here doesn't ONLY have to be used for supporting a workbench surface; or even a shelf. A person might want to do something like mount some sort of extra supports underneath a halfway-heavy paint booth's box or fan, or something like that, in a window opening ... and with a bit of planning and some careful exploratory drilling, this method would be one way to do it.

that work table came out great..ok your inspiring me to get my rear end in gear and start organizing my room